Pendulum Cooler®

More than 40 years of designing clinker coolers and over 800 installations and engineering consulting relating to the manufacturing of clinker coolers worldwide, prove that the IKN Pendulum cooler is at the forefront of technology.

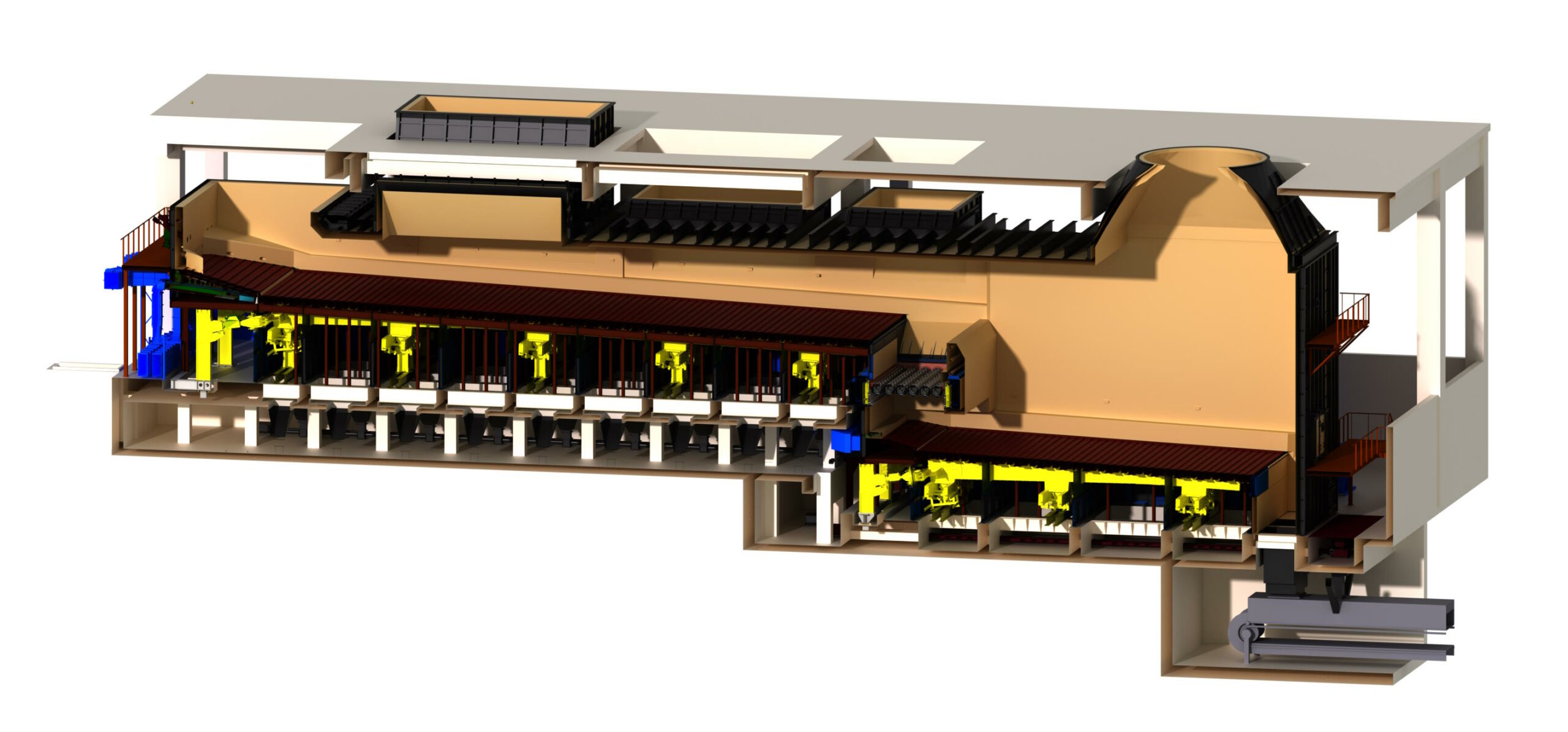

Following the stationary inlet (KIDS®), the Pendulum Cooler is divided into separate aerated compartments.

Optimized formation, aeration and transport of the clinker bed allow IKN Pendulum Coolers to operate at higher loads per m² of cooler surface. Cold clinker discharge temperatures are maintained with the lowest air loading per kg of clinker.

The main features of the clinker cooler with Coanda Wings® are:

- Excellent clinker distribution resulting in uniform and efficient cooling of the clinker across the full width of the cooler

- Low construction height and compact design

- High thermal recuperation efficiency

- Robust and low-wear design make it easy to maintain leading to outstanding availability

- Modular design allows pre-assembly and reduces on-site assembly time

- Low electrical power consumption

All Sizes Available

IKN covers the entire clinker production capacity from 500 t/d to 15,000 t/d without compromising clinker or process quality.

Several IKN coolers with the capacities of more than 12,000 tpd have been put into operation during the last 15 years. One of them is installed in the largest clinker production line in the world and is producing 14,500 tons clinker per day. The total grate size is 300 m². Only 15 fans are required to provide the necessary cooling air.

In contrast, IKN supplied one of the smallest coolers with only 22 m² of aerated surface and 5 cooling fans with a nominal capacity of 900 t/d.

Coanda Wing®

The revolutionary design of the Coanda Wing® ensures optimum airflow into the clinker bed.

The assembled Coanda Wing® blades form narrow and curved slots in clinker transport direction. These openings generate sharp jets of air with high dynamic pressure. The Coanda effect forces the jets to curve parallel to the surface of the grate plate.

The air flow through the clinker purges fines from the clinker bed to the surface of the clinker.

The Coanda Wing® achieves the purging effect with minimum air flow and improved heat transfer between clinker and cooling air for maximum cooling and recuperation. The resulting clinker bed is characterized by its low resistance to the passage of cooling air.

Grate System

Horizontal air jets on the grate surface support clinker transport resulting in a reduction of the number of movable rows.

The size of the Coanda Wing® plates was designed to allow modular adaption of the grate width for varying kiln capacities.

Coanda Wing® plates, beams and mobile frames are precision-machined during manufacturing and laser aligned during installation. The resulting grate surface provides excellent mechanical operating characteristics with an optimal distribution of cooling air which maximizes heat transfer between the cooling air and clinker.

Linear Pendulum Support (LPS®)

Wear resistant and maintenance free spring steel straps of the LPS® require no lubricant and are easily accessible outside the cooler housing.

In conventional coolers the movable frame sags with time and the thrust gaps between the movable and fixed rows grow. To counteract this phenomenon, IKN developed the Linear Pendulum Support (LPS®).

The movable frame is supported by wear-free spring steel straps, which do not need lubrication. Due to the short length of these straps, the system is ideal for buildings with height restrictions.

Grate Drive

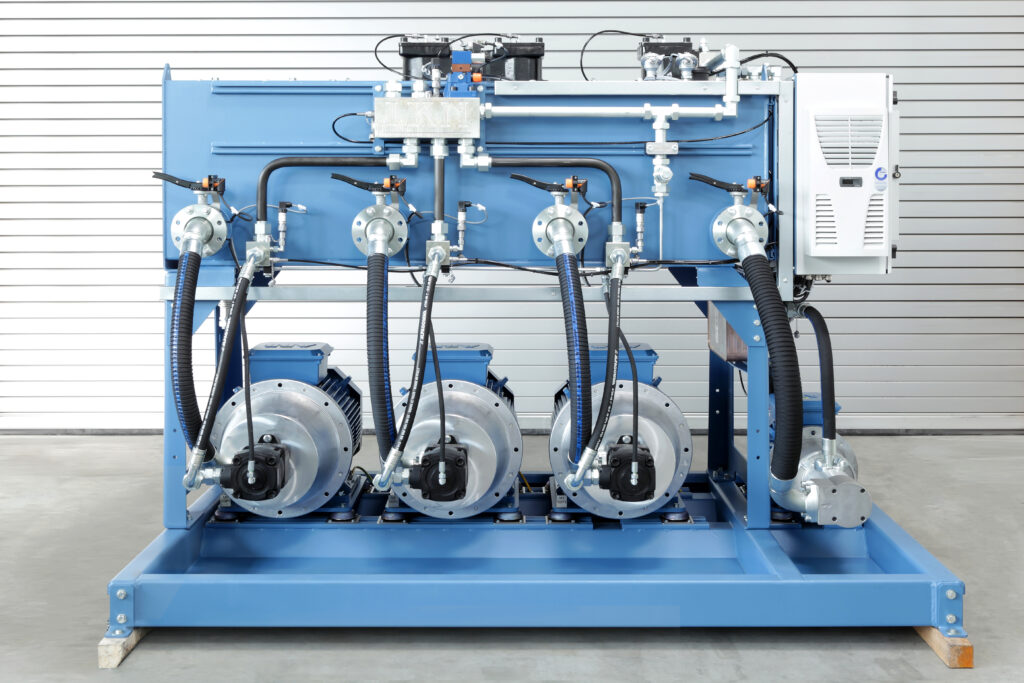

![]() A reliable grate drive is essential for optimum operation of the cooler and the entire kiln line.

A reliable grate drive is essential for optimum operation of the cooler and the entire kiln line.

All IKN drive systems can be programmed with an asymmetrical travel profile using slow forward and fast backward motion. This type of operation improves transport efficiency and balances the discharge into the clinker conveyor.

The grate drive is located outside the cooler housing protecting it from contamination by clinker dust and providing improved accessibility for maintenance. Depending on the size of the cooler, either a single drive or a synchronized twin drive is installed.

IKN grate drives are available as either hydraulic or electro-mechanical drive systems (DLD-Dynamic Linear Drive).

The mechanical DLD is the favorable option for new coolers as well as retrofits for all cooler sizes. The DLD significantly reduces the installation time since there is no need for an additional hydraulic room and hydraulic piping.

Hot Air Recirculation

Hot-air recirculation boosts efficiency of the waste heat recovery system.

Most Waste Heat Recovery Systems (WHRS) operate with a mid-air extraction of hot air.. The higher the recuperation efficiency, the lower the amount of available heat for WHRS. With the IKN Pendulum Cooler®, the plant can focus either on maximum recuperation or maximum WHRS output. Recirculation allows the operator to favourably influence the vent air ratio and the portion of air used for the WHRS. With maximum heat to the mid-air, the WHRS output can be significantly increased.

Roll Crusher

IKN Roll Crushers are operating in coolers with a capacity of up to 14,500 t/d. They offer low power consumption and low mechanical wear compared to other types of crushers.

The crusher can be installed at the cooler discharge or at an intermediate location dividing the grate into two grates with two separate drives. The rollers automatically reverse at high torque levels protecting the crushing rings against damage caused by foreign matter.

Typically, 95% of the crushed clinker is reduced to a particle size of less than 35 mm. The width of the crushing slots can be adjusted to the required particle size.